Set for complex decoking of the engine VMPAUTO art.8512

Quantity

Set for complex decoking of the engine VMPAUTO art.8512

It has never been so easy to return the engine to factory cleanliness and power

This technology is an alternative to overhaul and contract engine replacement. Allows you to eliminate defects caused by pollution and engine wear:

oil waste

vibration

power drop

engine starting problems

Provided that there are no mechanical failures of engine parts.

Complex decarbonization

Cleaning and rebuilding the engine

Stage 1 - Volumetric Cleansing

Stage 2 - Clean engine as from the assembly line

Stage 3 - Rebuilding and protecting the engine

Three steps to factory cleanliness

Step 1 - Foam decarbonization of the combustion chamber.

Beveling is the process of removing sparingly soluble deposits: high-temperature varnish, resins, soot, resistant to traditional washes.

Unlike liquid decarbonizers, it fills the entire volume of the combustion chamber, cleans nozzles and valves. Due to the five cycles of dissolution and rinsing, it works more effectively.

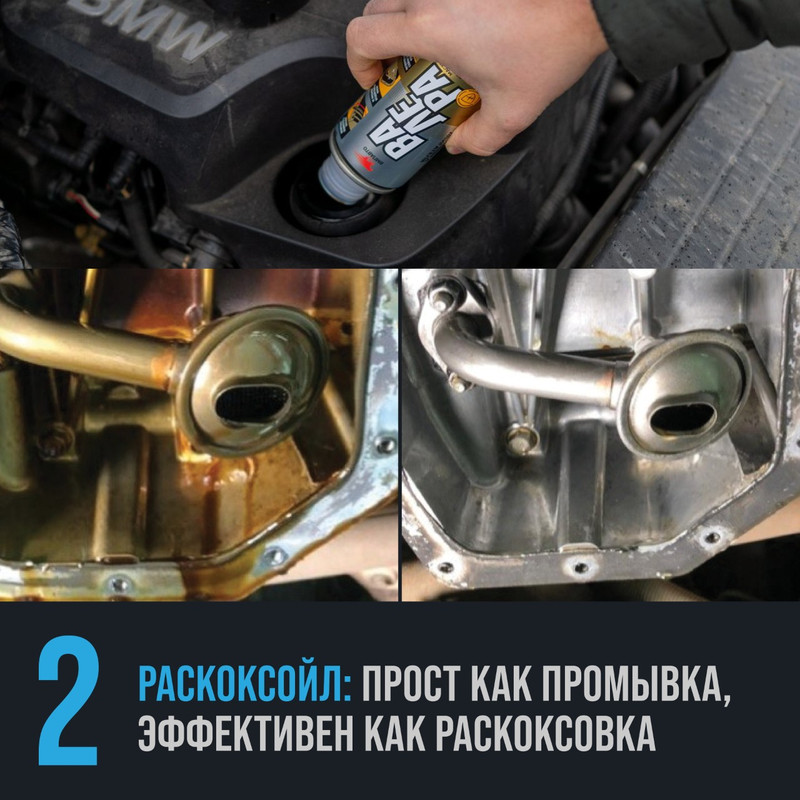

Step 2 - Raskoksoil.

This name belongs to an amazing product that is as easy to apply as a flush and works as powerfully as Decarbonizing.

Raskoksoil opens the piston drainage holes and restores the mobility of the oil scraper rings

In order for the engine to become clean, as from the factory, it is necessary to repeat the procedure 2-3 times.

Attention:

Do not leave used oil with Raskoksoil in the engine. After using decoke oil, it is necessary to drain the used oil and fill in fresh oil. Otherwise, engine parts may stick together due to the high concentration of dissolved resins in the used oil.

Step 3 - RESURS NEXT nanoconcentrate - the most compact engine treatment in the world.

Due to its high efficiency, price and compactness, it has gained popularity in various parts of the world: Nigeria, Mexico, Russia.

After the soot has been removed, it is necessary to protect the cleaned surfaces of the engine with metal nanoparticles. Particles use oil as a means of delivery to friction zones, where, under the influence of temperature and pressure, they block wear at the micro and meso levels, integrating into the crystal lattice.

Application

FOAM DECOXING OF VALER'S ENGINE

For cleaning the combustion chamber

Warm up the engine to operating temperature. Remove coils and spark plugs. Set the pistons to the middle position. The engine should be warm, but not hot.

Spray the composition into the candle well until it is completely filled with foam.

After the foam settles, let the composition react with soot for 5-7 minutes, then repeat steps 2 and 3. 5 repetitions are recommended.

Pump out the remains of the composition with impurities using a tube and a syringe, blow it with compressed air.

Cover all spark plug holes with a rag to prevent splashing of fluid.

Crank the engine over with the starter for 10 seconds.

Install all spark plugs and ignition coils.

Start the engine and let it run for 5 minutes. Thick smoke may come out of the exhaust pipe. It is necessary to increase the engine speed several times to 3000-4000 rpm until the smoke becomes less saturated.

On heavily polluted internal combustion engines, it is recommended to repeat the procedure after 10 thousand km.

It is advisable to change the engine oil and filter. To protect and restore ICE from wear, we recommend using RESURS (4302) metal cladding compounds.

To clean the intake manifold

Warm up the engine to operating temperature, disconnect the plastic part of the intake manifold. The engine should be warm, but not hot.

It is recommended to set the treated valves to the closed position.

Spray the composition into the intake manifold of the cylinder head until it is completely filled with foam.

After the foam settles, let the composition react with soot for 5-7 minutes, then repeat steps 3 and 4. 5 repetitions are recommended.

Remove the remains of the composition with impurities with a rag, then blow the collector with compressed air, covering the wells with rags. Avoid contact with skin, eyes, mucous membranes.

Reassemble the intake manifold, after which it is recommended to clean the combustion chamber.

RASKOKSOYL VALERA

Before use, keep the composition at room temperature for 6 hours

Check the oil level and select the correct dosage of the composition. The 100 ml bottle is designed for 4-5 liters of oil. With a different amount of oil, the dosage is not more than 25 ml per 1 liter of oil.

Warm up the engine to operating temperature, shut off, open the oil filler neck.

Pour the composition in the recommended dosage into the old oil or into the new flushing oil.

For effective cleaning of heavily contaminated internal combustion engines, it is necessary to keep the engine speed in the range of 1700-2300 rpm for 20-25 minutes.

Stop the engine and allow to cool to safely drain the used oil.

After application in internal combustion engines with a painted crankcase, it is necessary to check the integrity of the paintwork, if necessary, remove the paint.

Change oil filter and oil.

REMETALLIZANT RESURS

it is recommended to change the oil and filter

Warm up the engine to operating temperature and shut off

shake the vial vigorously for 20-30 seconds

pour the contents of the vial into the oil filler neck

let the engine idle for 10-15 minutes

Dosage - bottle 50ml

At a dosage of more than 2 bottles, the drug should be poured through small intervals of run (50-100 km)