Set of 6 AZTA PREMIUM diamond stones on MO bond

Quantity

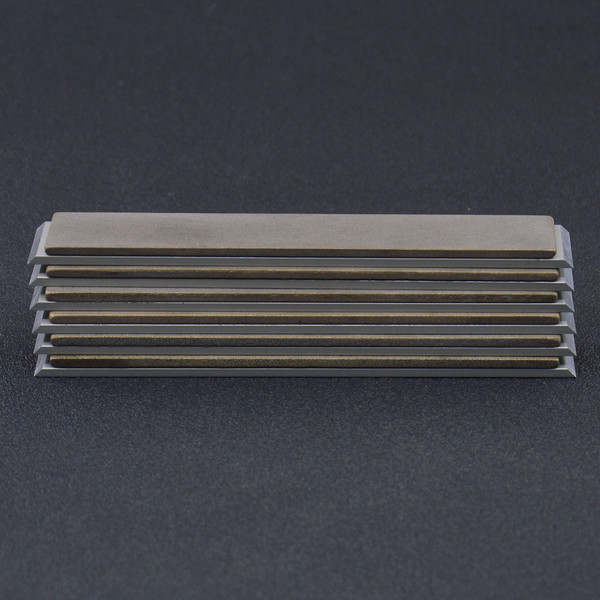

Set of 6 AZTA “PREMIUM” diamond stones on MO bond 100%, 160x25x6 mm

Professional set of diamond stones on a metal bond and aluminum blanks from TOMILINSKIE DIAMONDS ABRASIVE PLANT.

Weight

0.75 kg

Dimensions

16 × 2.5 × 5 cm

Manufacturer

AZTA (TOMILINSKIE DIAMONDS ABRASIVE PLANT)

Country of Origin

Russia

Usage

for sharpener ZHUK, for APEX format

By purpose

set of bars

Type

unilateral

By appearance

oil

Bundle type

copper-tin

Abrasive material

diamond

Diamond whetstones from Tomilinskiye Almazy Abrasive Plant

High productivity and efficiency are achieved by using a 100% concentration of diamonds, and durability is achieved by a metal copper-tin bond that firmly holds the diamond grains during operation.

Abrasive

Diamond

Bunch

Copper-tin (M)

Bar thickness

3 mm

Working surface size

150 x 25 mm

Monolayer block on a blank for APEX EDGE/ZHUK sharpeners – 150x25x3 mm.

The bars are made of tin bronze and copper with special additives.

Diamond stones are the most productive, efficient and durable of abrasive stones.

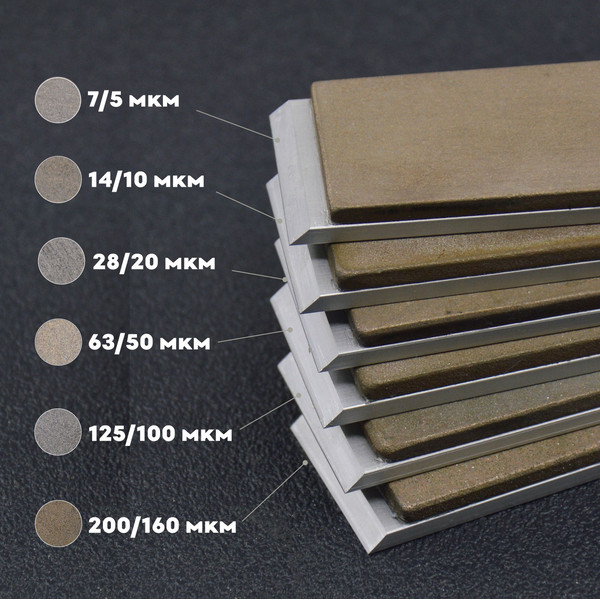

6 stages of knife care

For all types of work, from rough sharpening to polishing.

200/160 µm

Used for rough sharpening.

JIS: 85 grit, FEPA: 80 grit.

125/100 µm

Used for rough finishing during roughing.

JIS: 120 grit, FEPA: 110 grit.

63/50 µm

Used for fine finishing during roughing.

JIS: 240 grit, FEPA: 220 grit.

28/20 µm

Used for fine sharpening.

JIS: 500 grit, FEPA: 360 grit.

14/10 µm

Used for preliminary, fine finishing.

JIS: 1000 grit, FEPA: 600 grit.

7/5 µm

Used for fine finishing.

JIS: 2200 grit, FEPA: 800 grit.

Wooden box as a gift!

Wooden box for storing sharpening stones. In addition to the 6 bars from the AZTA “Premium” set, you can place 2 additional stones in the box.

ABOUT THE BOX

Go straight to battle!

PREMIUM series bars are brought to the same thickness within 3.0 – 3.1 mm and chamfered.

They have a record service life of up to 3000 sharpening cycles and more.

Diamond stones do not need to be prepared before use; the stone is immediately ready for use.

The bars are restored at Bodrid from white electrocorundum.

Branded engraving on forms

Engraving on the form will prevent the bars from becoming confused and will help you quickly navigate between them.

The blank is very rigid in bending. Anodizing gives a beautiful appearance, protects against oxidation, and prevents contamination.

The end of the blank is chamfered at an angle of 45 (“dovetail”) for mounting in a sharpener holder. This fastening allows you to create tension and a pressing effect when fixing the form.

The bars are glued to the form using special glue.

Quality assurance

All bars that go on sale undergo the manufacturer's quality control department. Each batch of bars is accompanied by a general certificate of conformity with a QC mark.

Upon acceptance, we check the bars again. Anything that can in any way affect the quality of sharpening is rejected!